Made to Measure

Customised solutions for every production requirement.From plant dimensions to workpiece loading and unloading, we design customised industrial sawing machines to suit your space, your flow and your goals.

Dimensions

Each cutting line can be optimized based on available space. Whether compact systems for tight spaces or large solutions for large volumes, we design saws that can be adapted in length, footprint, and layout configuration, without compromising performance and accessibility.

Load

We design customized automatic loading systems, capable of handling bars or tubes of any length, or special formats.

We adapt the system according to the type of material and the loading frequency, to ensure efficiency and

continuity of production.

I unload

Each system can be equipped with custom unloaders, with customized sorting, separation of good and rejected parts, or integration with conveyors, belts, and scales for weighing. The layout is designed based on the production flow to reduce time and movement.

Do you want more information?

Contact us. We will get back to you as soon as possible.

How we work

Customer analysis and comparison

Every project begins with a direct meeting with the customer. We analyse production requirements, space constraints, type of material and objectives together. This initial confrontation is essential to gather all the necessary technical information and to set up a truly effective proposal. Our experience allows us to immediately focus on the details that will make the difference in the operational phase.

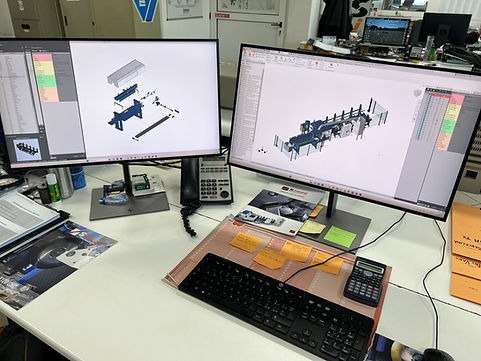

Design and Layout

Based on the information gathered, our technical team develops a tailor-made solution, defining each part of the line: dimensions, automations, loading/unloading systems, special configurations.

Through demonstration layouts and technical simulations, we present the customer with a concrete vision of the project. The comparison è constant and allows us to optimise every detail before production, adapting the plant to the real conditions of the working environment.

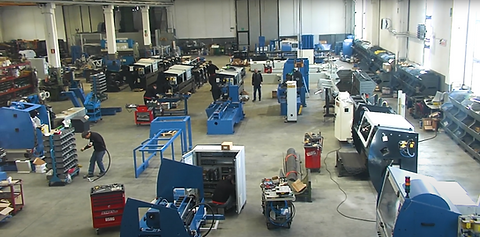

Production

Once the design is approved, we start the complete construction of the cutting line. Each machine is manufactured in-house in our factories, following high standards of quality, precision and reliability. From the main plant to customised accessories, every component is checked and tested during the entire production process.

Testing and installation

Before delivery, the customer è invited on site to check the functioning of the plant through a complete test, with cutting tests and testing of all integrated systems.

Subsequently, our team takes care of the assembly at the customer's premises and the commissioning of the machine. The second operational test ensures perfect integration into the production cycle.

At this stage we also provide training in use, technical documentation and assistance, to deliver a plant ready for use in complete safety.

Dimensions

Each cutting line canvarying sizesto fit the spaces availablein the plant.We can rreduce or extend the overall length, change the depth of modules and manage compact or developed layoutswithout compromising the efficiency of the cutting cycle.

A

From 8 to 30 [m]Cutting Line Length

Copyyright

The loading system is configured according to the type of material, the lengthof the bars or of the pipes, and to the feeding mode required.

Thereby, in addition to the length, the components could also be modified.

From short bars individually loaded up to 12-metre bars, each system can be adapted with customised loaders and customised automatisms.

A

Pipe Unloader: Customisable in size and equipment, depending on length and type of material.

B

Bar loader: Modular structure, adaptable to suit the size and method of feeding.

Dump

The drainage area canò be designed to sorting parts in different directions (frontal, lateral), to automatically separate rejects and good parts, or to integrate gums, weighing, and collection forms.The aim is always the same: to optimise the final flow, according to the customer's layout and process.

A

Bar unloader:Adaptable in length and direction of exit, depending on layout.

B

Bar unloader with straps:Modular with accessories and automatic collection systems.

Customisable elements

Each Simec line è consists of modules designed to be configurable according to actual production conditions. From the length of the machine to the arrangement of the loaders, from the unloading of parts to the management of the scrap, each section of the plant can beoptimised to suit the customer's layout, improving ergonomics and productivity.