Furnishing sector

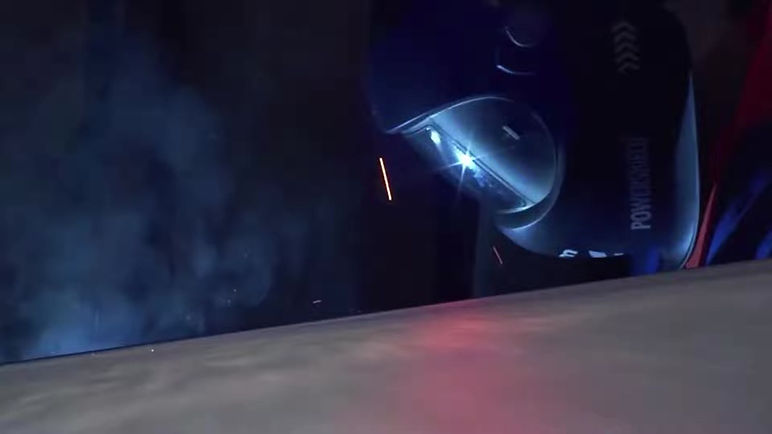

The furniture sector, in particular technical, industrial and design furniture, makes extensive use of tubular metal structures to make tables, seats, shelving, frames, displays and furnishing accessories for civil, public or commercial spaces. Specialised suppliers cut tubular steel, aluminium or stainless steel with high quality finishes, taking care of aesthetics, clean cut and geometric repeatability. In many cases they work in small to medium series, but with the need for great flexibility and speed.

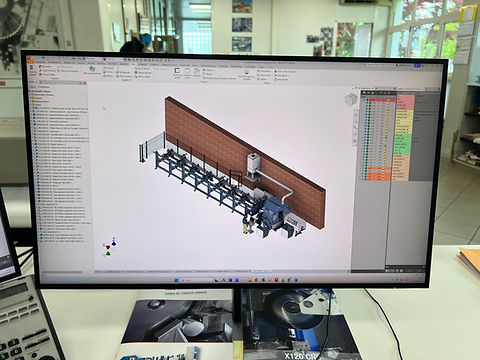

Simec machines ensure aesthetic and precise cuts, ideal for visible components or aesthetic finishes. With flexible batch management and the ability to process different materials without reconfiguring the system, each line is perfect for just-in-time production. Our technologies help furniture companies ensure consistent quality, production speed and application versatility.

Key points

aesthetic and precise cutting for exposed tubulars

.

Versatile handling of different designs and materials

Compatibility with aluminium and stainless steel

Fast set-up for just-in-time production

Ideal for interior and exterior furnishings

Why choose our Simec machines

Want more information?

Contact us. We will get back to you as soon as possible.

Products that can be produced

Industry 5.0

Our machines embrace the principles of Industry 5.0, promoting perfect collaboration between man and technology. We offer advanced solutions where automation is combined with flexibility and customisation, putting the operator and the customer's specific needs at the centre. Intelligent data integration enables more sustainable, adaptive and quality-oriented production processes. Every Simec system contributes to a more advanced industry, where efficiency, responsibility and innovation are in balance.

Spare parts available in stock

Frequent changes and customised requests? No problem. Our spare parts service is designed to guarantee speed, compatibility and continuity, even in the case of seasonal production or non-standard items.

Simec for you

Simec manufactures systems designed to machine steel, stainless steel and aluminium tubes with speed and precision. Our machines are designed to support the variety typical of modern design: different sizes, special formats, small batches or series production. With us you have a partner that combines technology, craftsmanship and customisation to accompany every stage of production growth.