Subcontracting of components for industrial vehicles

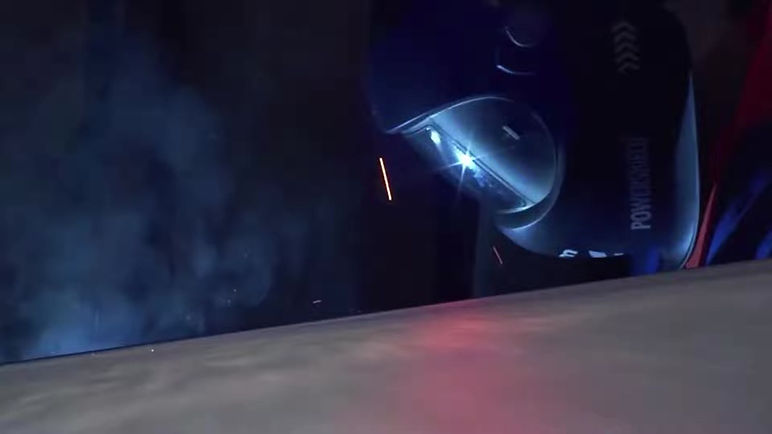

Subcontracting for industrial vehicles includes all those companies that manufacture structural or functional components for heavy vehicles such as excavators, cranes, earth moving machines, trucks or special vehicles. These suppliers deal with the machining of bars, tubes and semi-finished products in steel or high-strength alloys, producing elements such as joints, arms, brackets, frames and cylinders.

The sector requires precision, solidity and the ability to adapt to customised production, often in small batches or to very detailed technical specifications. The quality of the cut and the reliability of the machining are fundamental to guarantee high performance and operational safety in the finished products.

In the world of industrial vehicles, every component must guarantee mechanical strength, precision and durability. Simec sawing machines are designed to cope with tough materials and complex sections, ensuring clear and repeatable cuts even on mixed or non-standard batches.

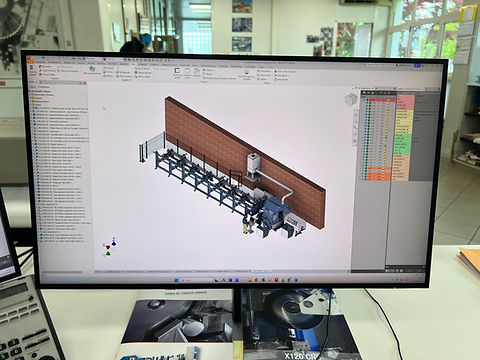

Thanks to the tailored configuration, our lines can be adapted to any requirement: from cutting pipes for frames to semi-finished products for plumbing systems or supporting structures. Each plant can be integrated with automatic loading/unloading systems, quality control and remote diagnostics, in line with Industry 4.0 requirements.

Key points

Precise cutting on strong materials

.

Customised solutions for every component

Compatibility with 4.0 systems

Reduction of scrap and cycle times

Reliability in intensive production cycles

Why choose our Simec machines

Want more information?

Contact us. We will get back to you as soon as possible.

Products that can be produced

Industry 5.0

Our machines embrace the principles of Industry 5.0, promoting perfect collaboration between man and technology. We offer advanced solutions where automation is combined with flexibility and customisation, putting the operator and the customer's specific needs at the centre. Intelligent data integration enables more sustainable, adaptive and quality-oriented production processes. Every Simec system contributes to a more advanced industry, where efficiency, responsibility and innovation are in balance.

Spare parts available in stock

Every production stoppage is a cost, which is why Simec guarantees the availability of spare parts in the shortest possible time, with a complete stock of mechanical and electronic components and consumables always ready in stock.

.Each spare part is original and 100% compatible with your machine's configuration, even years after installation.

.

Thanks to a structured technical support and rapid dispatch service, we ensure continuity of operation even in the most intensive and made-to-order productions.

Simec for you

Simec has been supporting subcontractors in the industrial vehicle sector for years, designing tailor-made saws for high-intensity and constant precision production. Our systems are designed to process strong>durable materials and complex sections, guaranteeing speed, repeatability and integration with existing production flows.

From the single machine to the complete line, we build solutions capable of coping with continuous production cycles, adapting to variable layouts and increasingly challenging demands.

With us you have a solid, flexible technical partner ready to accompany you over time with technology, expertise and real support.