Hydraulic and pneumatic components

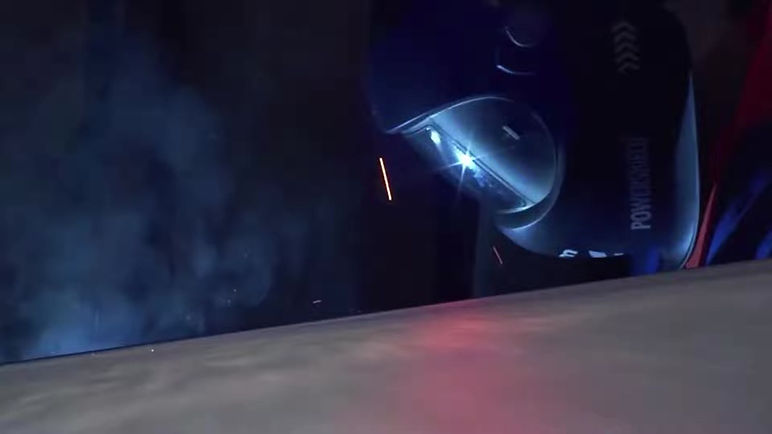

e companies in the hydraulics and pneumatics sector produce key components for fluid handling and control systems: cylinders, pistons, pipes, flanges, valves and fittings. Machining requires absolute precision, clean surfaces and clean cuts to ensure system tightness and durability. The materials used range from high-strength steels to stainless steels and special alloys, often under complex, high-volume production conditions.

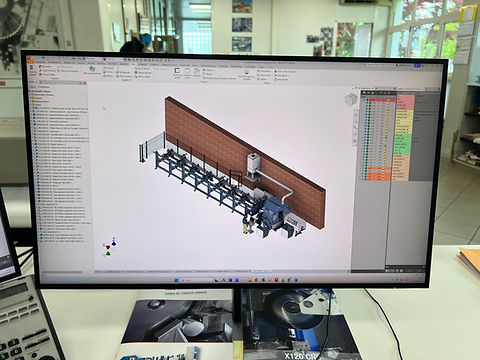

Simec lines are developed to achieve perfectly orthogonal cutting surfaces, minimising subsequent machining and ensuring absolute repeatability. Their operational flexibility allows different machining operations to be tackled with the same system, while intelligent monitoring and diagnostics systems increase overall efficiency. The cutting quality and integration 4.0 are ideal for supporting production cycles as rigorous as those of hydraulics.

Key points

Maximum precision and cleanliness of the cut

Reduction of post-cutting processing

Versatility on variable materials and diameters

Right-angled cuts ideal for mechanical couplings

Technology 4.0 for traceability and diagnostics

Why choose our Simec machines

Want more information?

Contact us. We will get back to you as soon as possible.

Products that can be produced

Industry 5.0

Our machines embrace the principles of Industry 5.0, promoting perfect collaboration between man and technology. We offer advanced solutions where automation is combined with flexibility and customisation, putting the operator and the customer's specific needs at the centre. Intelligent data integration enables more sustainable, adaptive and quality-oriented production processes. Every Simec system contributes to a more advanced industry, where efficiency, responsibility and innovation are in balance.

Spare parts available in stock

When cutting high-precision parts, operational continuity is everything. That is why Simec offers a comprehensive spare parts park, with certified parts and direct technical support, designed to minimise downtime and maintain stable quality.

Simec for you

Precision is at the heart of everything we do. Simec specialises in the construction of high-performance industrial sawing machines, ideal for manufacturing hydraulic and pneumatic components. We invest in CNC technology, intelligent software and advanced automation to offer machines that can meet the most demanding requirements. All with the reliability of a entirely Made in Italy brand.