Moulding Industry

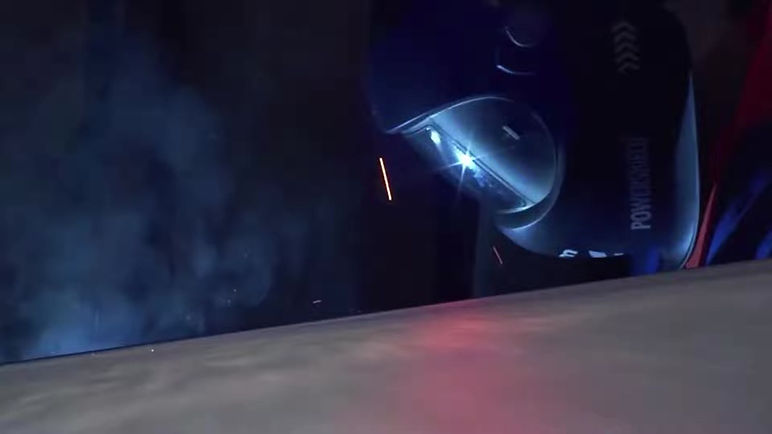

Hot stamping is a fundamental process for the production of high-strength structural components for sectors such as automotive, hydraulics, construction machinery and general mechanics. It all starts with precise cutting: solid bars are cut to length before being heated and deformed in moulds.

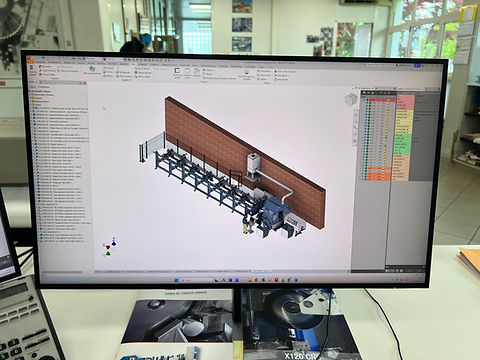

Simec sawing machines are designed to offer reliability, continuity and precision at the initial stage of the hot stamping process. The quality of the cut is crucial to ensure correct mould filling and to reduce scrap: our machines ensure clear, consistent and perfectly perpendicular cuts even on high-strength moulding steels.

With robust structures, customisable configurations and high-productivity automated systems, each line is designed to optimise cycle times and reduce downtime. Our customers in the forging sector find in Simec a reliable partner to guarantee process efficiency, consistent quality and a forging-ready cut.

Key points

High performance on special steels and alloyed materials

.

Dimensional repeatability for critical components

Integrated traceability and Industry 4.0 compatibility

Real-time quality control

Optimisation of scrap and cycle times

Why choose our Simec machines

Want more information?

Contact us. We will get back to you as soon as possible.

Products that can be produced

Industry 5.0

Our machines embrace the principles of Industry 5.0, promoting perfect collaboration between man and technology. We offer advanced solutions where automation is combined with flexibility and customisation, putting the operator and the customer's specific needs at the centre. Intelligent data integration enables more sustainable, adaptive and quality-oriented production processes. Every Simec system contributes to a more advanced industry, where efficiency, responsibility and innovation are in balance.

Spare parts available in stock

Reliability also means having quality spare parts available at all times. Simec ensures fast service and spare parts that are always compatible with the specific configuration of your machine, even years after purchase.

Simec for you

In the automotive world there is no room for inaccuracy. Simec provides equipment that is reliable, fast and capable of meeting the highest production standards in the industry. We offer tailor-made cutting solutions, configurable to existing volumes, materials and layouts. Each machine is the result of continuous technical research, geared towards maximum efficiency, repeatable quality and durability.