Parts Manufacturers

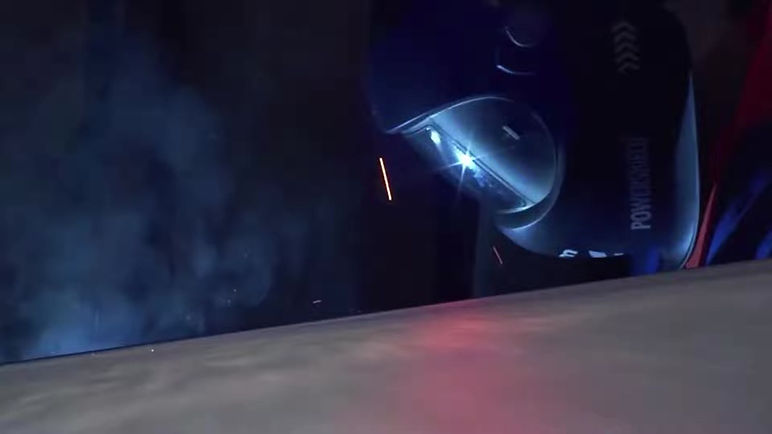

Metal subcontracting companies play a key role in the production of structural and mechanical components for many sectors: machinery construction, agricultural vehicles, industrial plants and steel structures. These companies cut, assemble and weld tubes and bars, producing frames, brackets and supporting structures. The demand for high precision, long-term reliability and production flexibility is increasingly central to remaining competitive in an ever-changing market.

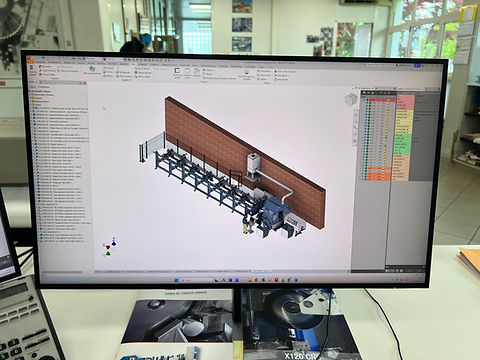

Simec's cutting solutions are designed to meet the needs of Parts Manufacturers They offer maximum versatility for machining steel and alloy bars and tubes, maintaining high quality standards even on intensive production runs. The integration of automatic loading and unloading, the speed of changeovers and the possibility of customising each line according to space and operational needs, make our machines a real ally in managing contract work. In addition, process monitoring and Technology 4.0 allow precise control of production times and costs, optimising efficiency.

Key points

Precision and repeatability even on structural parts

Quick cutting of tubes and bars in steel and special alloys

Reduction of cycle times and manual labour

Customised loading/unloading systems

Reliability on intensive shifts and mixed production

Why choose our Simec machines

Want more information?

Contact us. We will get back to you as soon as possible.

Products that can be produced

Industry 5.0

Our machines embrace the principles of Industry 5.0, promoting perfect collaboration between man and technology. We offer advanced solutions where automation is combined with flexibility and customisation, putting the operator and the customer's specific needs at the centre. Intelligent data integration enables more sustainable, adaptive and quality-oriented production processes. Every Simec system contributes to a more advanced industry, where efficiency, responsibility and innovation are in balance.

Spare parts available in stock

In contract work, continuity is fundamental. With Simec you can count on a rapid spare parts supply network, with immediate availability of the parts most subject to wear and timely technical support to get production back up and running quickly.

Simec for you

Simec supplies strong>robust and flexible saws, designed to meet the needs of contract carpentries. Each system is born from a mix of mechanical expertise, digital innovation and craftsmanship, with the aim of offering reliable, precise and durable machines. Extremely customised is our hallmark: every detail is designed to fit the actual machining and space requirements.