Oil & gas sector

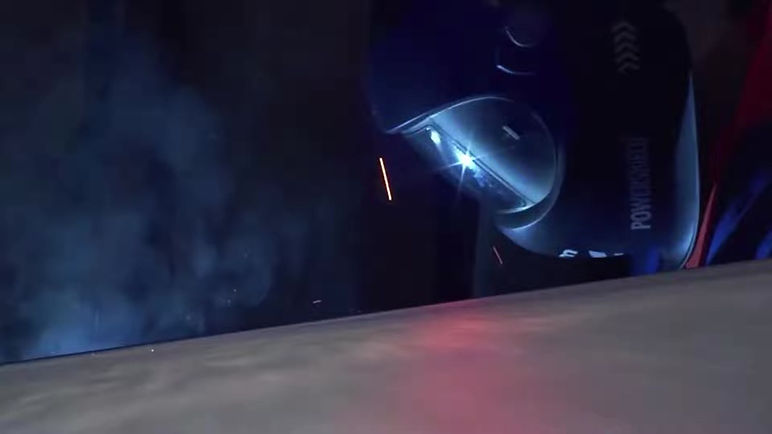

The Oil & Gas industry requires highly reliable components that can withstand extreme pressures, corrosives and harsh operating conditions. Valves, fittings and other fluid control devices are made from high-performance materials such as stainless steels, special alloys and super alloys and require precise and repeatable machining.

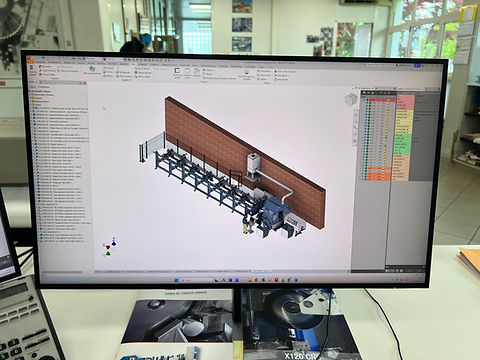

Those involved in contract manufacturing of valves for oil, chemical and energy plants need accurate, robust cutting lines that can handle difficult materials while ensuring traceability, consistent quality and optimised cycle times.

Machining operations often start from solid bars or tubes of special section, destined to become control, safety or shut-off valves. For this reason, cutting operations represent a crucial stage in the production process.

Machining for the Oil & Gas sector requires precise cuts, strong>strong>resistant materials and tight tolerances. Simec sawing machines are designed to cope smoothly with stainless alloys, duplex and special materials, ensuring reliability and consistent quality even on complex batches. Each plant is customised and compatible with Industry 4.0, offering repeatability, integration into production flows and continuous technical support. A concrete solution for those looking for high performance and business continuity.

Key points

High precision cutting even on critical materials

.

Reliability, ideal for complex components

Guaranteed dimensional repeatability, even on variable geometries

Compatibility with Industry 4.0 for traceability and diagnostics

Customised configuration for vertical production flows

Why choose our Simec machines

Want more information?

Contact us. We will get back to you as soon as possible.

Products that can be produced

Industry 5.0

Our machines embrace the principles of Industry 5.0, promoting perfect collaboration between man and technology. We offer advanced solutions where automation is combined with flexibility and customisation, putting the operator and the customer's specific needs at the centre. Intelligent data integration enables more sustainable, adaptive and quality-oriented production processes. Every Simec system contributes to a more advanced industry, where efficiency, responsibility and innovation are in balance.

Spare parts available in stock

Every detail counts when working with precision. Simec guarantees original components and comprehensive spare parts support, to ensure accurate cuts even after years of use. A service designed to minimise downtime and maximise efficiency.

Simec for you

Simec designs and manufactures cutting systems suitable for even the most specialised work, such as those in the hydraulic field. For over 35 years we have been committed to offering flexible, fast and intelligent solutions, with a special focus on accuracy and waste management. Our machines are built to simplify production flows and reduce tooling times, adapting perfectly to every need of the modern subcontractor.