Cutting service centres

Service centres represent a fundamental link in the metalworking supply chain, carrying out contract operations such as cutting, preparation and machining of tubes and bars in steel, stainless steel, light alloys and special materials. They work on behalf of customers in numerous sectors - from automotive to mechanical engineering, from furniture to plant construction - offering precise, fast and customised machining. Efficiency, material traceability and the ability to handle high production volumes are key factors here.

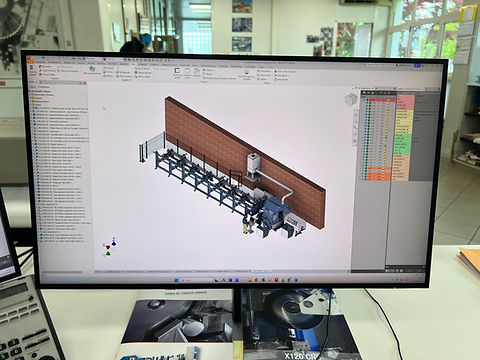

Simec machines are a strategic solution for service centres wishing to increase productivity without compromising quality. Our cutting lines guarantee high processing speed, millimetre accuracy even on large batches, and the maximum flexibility in handling different materials, lengths and diameters. Thanks to customisable modular configurations, each plant can be adapted to the customer's specific production layout, optimising space and workflows. Integration with management software and Industry 4.0 systems allows advanced control of production data, complete traceability of machined parts and the possibility of performing predictive maintenance for continuous efficiency. In an industry where time and precision make all the difference, Simec offers reliability, innovation and constant support to accompany the growth of cutting centres.

Key points

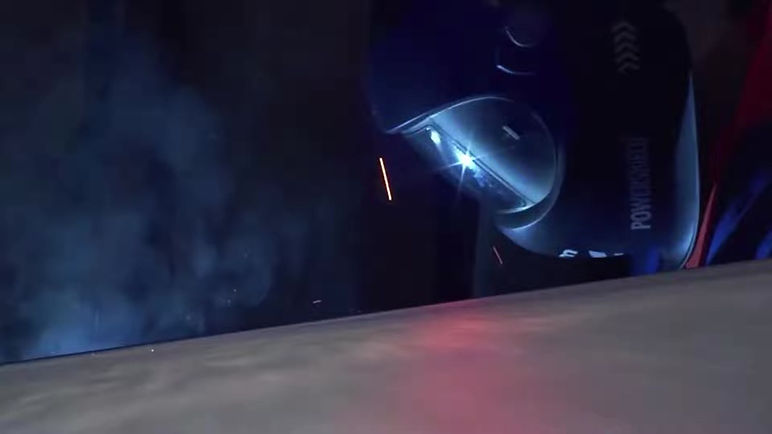

High precision cutting on tubes and bars of various materials

.

Full automation of work cycle

Flexibility in handling different batches and lengths

Integration with ERP systems and Industry 4.0

Modular configurations adaptable to any production layout

Why choose our Simec machines

Want more information?

Contact us. We will get back to you as soon as possible.

Products that can be produced

Industry 5.0

Our machines embrace the principles of Industry 5.0, promoting perfect collaboration between man and technology. We offer advanced solutions where automation is combined with flexibility and customisation, putting the operator and the customer's specific needs at the centre. Intelligent data integration enables more sustainable, adaptive and quality-oriented production processes. Every Simec system contributes to a more advanced industry, where efficiency, responsibility and innovation are in balance.

Spare parts available in stock

For service centres, every downtime is a cost. That is why Simec ensures always available spare parts, from mechanical parts to electronics and consumables.strong>consumables, with rapid shipping and original components guaranteed to keep your system up and running.

Simec for you

Simec has been working alongside service centres since 1987, designing tailor-made cutting lines for contractors. Our goal is to offer precision, reliability and continuity of production through customisable solutions that are fast and always up-to-date with the latest technology. We develop systems that fit perfectly into any industrial context, guaranteeing maximum efficiency and constant support over time.